CNC Router Tables

-

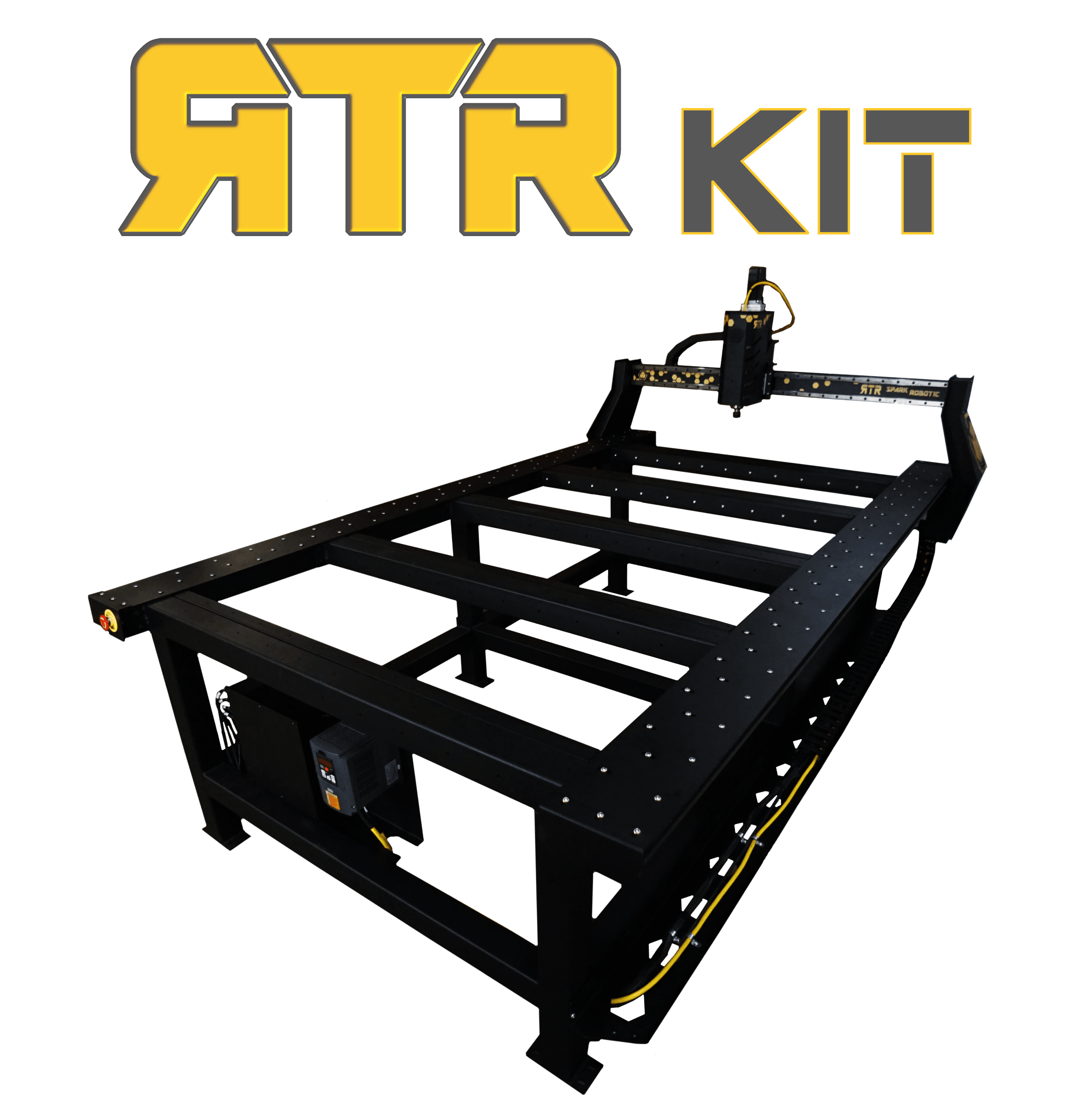

RTR KIT Series

Shop RTR KIT SeriesModular design that can be configured to fit in any workspace.

• Available in sizes 4'x4' & 4'x8'

-

RTR PRO Series

Shop RTR PRO SeriesFully welded steel frame, engineered for maximum rigidity.

• Available in sizes 4'x4' 4'x8' 4'x12' 5'x10' & 6'x12

-

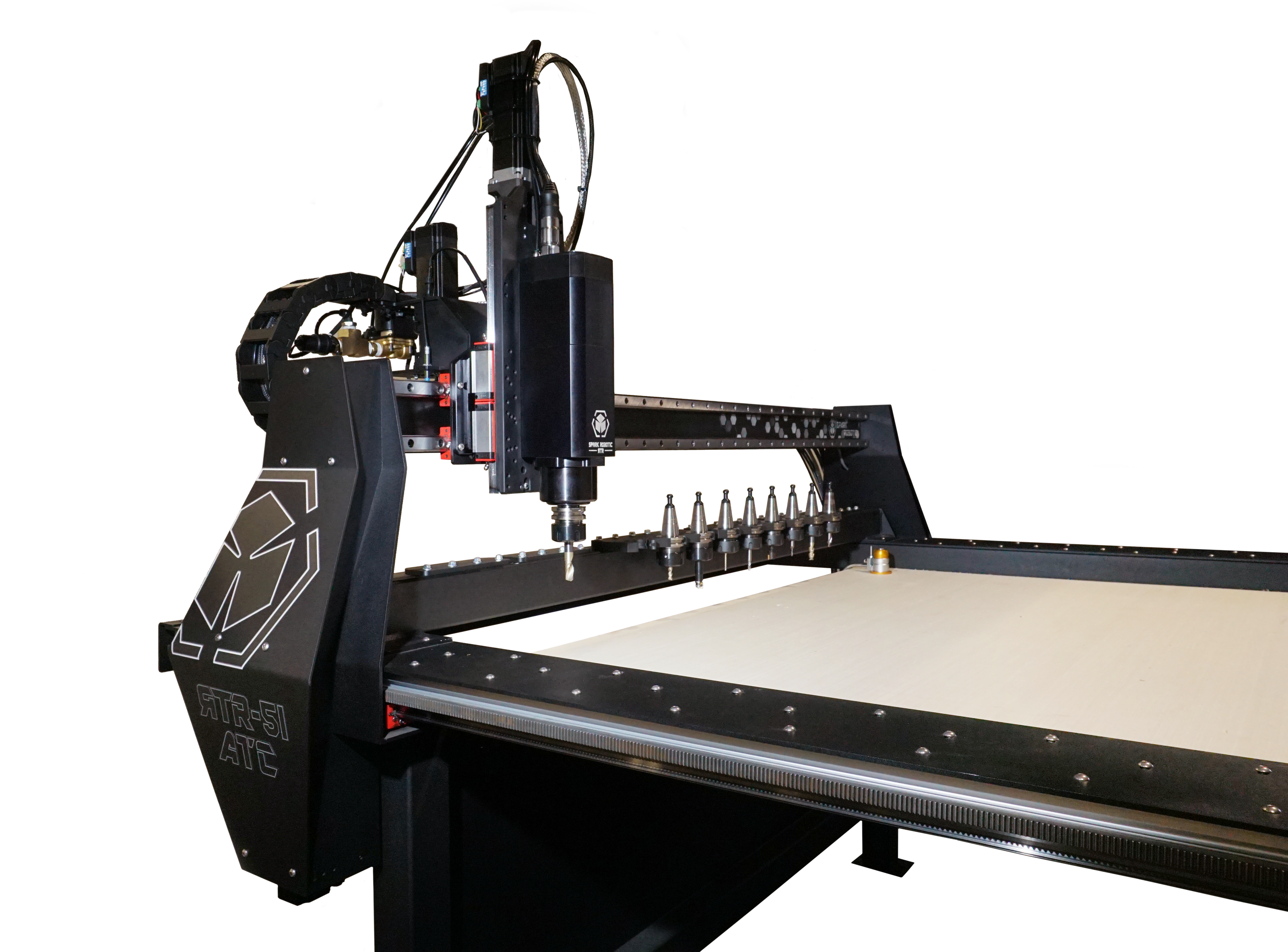

RTR PRO ATC Series

Shop RTR PRO ATC SeriesThe RTR PRO with integrated robotics of an Automatic Tool Changing spindle.

• Available in sizes 4'x4' 4'x8' 4'x12' 5'x10' & 6'x12

CNC Router Tables from Spark Robotic

Building upon the proven success of our industrial XR Plasma Series, our RTR Series CNC Router Tables share a robust design foundation known for its durability and performance. In addition, our router tables incorporate several key innovations specifically engineered to excel in various routing applications.

Our goal was to create a series of high-performance CNC routers that deliver exceptional precision, speed, and reliability, all at a competitive price point.

At Spark Robotic, we understand the importance of balancing capability with a budget to empower businesses and makers of all types.

Our RTR Series CNC Router Tables outperform the competition while offering a cost-effective solution. Our extensive prototyping, research, and testing has proven to deliver exceptional cutting accuracy in a wide-range of materials, including wood, foam, composites, and non-ferrous metals.

Spark Robotic offers a variety of RTR Series models to cater to diverse project requirements. Explore the technical specifications and functionalities of our RTR Series CNC Routers in more detail below. Discover how these innovative machines can streamline your workflow, add immense value to your shop, and empower your creativity to conquer any project.

Router Table Specs

FRAME DESIGN

- The RTR Router Kit has a modular designed frame that is incredibly rigid, but is simple enough to assemble the frame base in around 30 minutes.

- The RTR Router Kit has laser-cut steel tubing with oversized "tab and slot" plates welded on each end. These plates make for large, flat mating surfaces that join together perfectly, allowing for a massive amount of clamping force.

- The RTR PRO Router frame is fully welded, which makes for the ultimate router design.

- Laser-cut steel tubes and fully welded frames are powder coated in-house.

- Unlike many of our competitors, we use American-made steel in the structural components of our tables instead of extruded aluminum.

- 50+ holes for mounting a table board.

- Heavy-duty, hardened, precision 23mm linear rails.

- All components in both models are welded using laser cut and laser aligned jigs to insure perfect construction and repeatability.

- Both Router models come with a fully welded steel gantry.

DRIVE SYSTEM

- High-Power Servo motors on all axes

- Both RTR Routers use HG-23 linear bearings

- Gear and rack drives on both the X and Y axes

- The Z axis is reverse-mounted to keep dust and debris off the ball screw and bearings, as well as to maintain maximum rigidity near the bit--exactly where you want it.

- Precision mechanical gear reductions on both the X and Y axes.

- High-Power Servo motors on all axes with true feedback and the ability to monitor follow error.

- Both RTR Router models use HG-23 linear bearings.

- Gear and rack drives on both the X and Y axes.

- The Z axis is reverse-mounted to keep dust and debris off the ball screw and bearings, as well as to maintain maximum rigidity near the bit--exactly where you want it.

- Precision mechanical gear reductions on both the X and Y axes.

- Automotive style wiring harness.

- Optional Heavy duty Z axis made in house with a billet Z and X plate, 4 large linear bearings, and around an additional 2" of z travel.

SPINDLE & VFD

- Our CNC routers come standard with an air-cooled 3 horsepower spindle controlled by a VFD (variable frequency drive) with an RPM range of 8k to 24k. This spindle is 220v / 6 amp but can be run on 110v with a 'Step up'.

- The spindle uses ER-20 to hold cutters up to 1/2" and comes with a 14-piece collet set from 1/2" all the way down to 1/16".

- The VFD is completely controlled by the integrated software. Your g-code will automatically set the spindle RPM, so you won't need to turn the spindle on or off or set the RPM before each cut.

- There is also an upgrade option for a Hiteco 4hp ER-25 MTC spindle or a Hiteco 5.5 HP IOS-30 ATC Spindle.

SOFTWARE & CONTROLLER

- We tested over a dozen different Control software packages and chose Planet CNC because it supports our customers' needs while also being comprehensive, customizable, and user friendly.

- Planet CNC is capable of 9-axis control with 8 digital outputs and 3 PWM outputs.

- Planet CNC TNG control software is included with the purchase of both Router models and is customized by us to ease use and optimize workflow.

- Windows laptop is included with the the machine. There is also an upgrade option for a high-spec laptop to support CAD and CAM programs.

MOTORS

- The accuracy and speed of high-power, closed-loop servo motors are without comparison. We have run these machines at over 3000 in/min (in the air) without losing any steps.

- High-Power Servo motors on all axes with true feedback and the ability to monitor follow error locally.

Feed Rates:

- Rapid traverse (X/Y/Z): 3000 in/min (software limit set to 500 in/min, but this can be changed by the customer)

- Max cutting feed rate (X/Y/Z): 3000 in/min (software limit set to 500 in/min, but this can be changed by the customer)

- This combination of performance and reliability is what our customers expect from Spark Robotic. On top of all the other design and engineering choices we made, we're excited to be able to feature these servo motors on all of our routers while managing to keep our prices lower than the competition.

POWER REQUIREMENTS

- 2x 110V outlets for controlling the unit and the laptop

- 220V outlet, 6 amp for spindle

-

Warranty

- Electrical: 2 years

- Mechanical: 2 years

- Laptop: 3 months

- Spindle: 1 Year Warranty

- Third Party equipment and products are subject to warranties provided by the original manufacturer or supplier. Third party warranties may vary from product to product.

-

Shipping

The RTR Series Routers come fully-welded or as modular kits that can be assembled in your own workspace. Your order can be freight shipped or picked up at our production facility in Mars Hill, North Carolina. A forklift is required to safely unload the machine from the freight truck. 6ft pallet forks can handle the unloading, but 8ft forks are recommended for 5x10 machines and larger. *This is solely the responsibility of the customer. A complete listing of our shipping policies can be found here.

- RTR-44 PRO crate is roughly 73" x 68" x 73" & weighs about 1100 LBS

- RTR-44 KIT crate is roughly 73" x 56" x 37" & weighs about 950 LBS

- RTR-84 PRO crate is roughly 120" x 68" x 73" & weighs about 1375 LBS

- RTR-84 KIT crate is roughly 120" x 56" x 37" & weighs about 1285 LBS

- RTR-51 PRO crate is roughly 140" x 88" x 60" & weighs about 1550 LBS

Watch the Router in Action!

Featured Customer Projects

Enhance your order with our Router accessories.

For any questions, reach out to router@sparkrobotic.com